GDIS-E2000brief introduction

With the rapid development of Internet plus and the Internet of Things, the system realizes centralized and unified management of equipment in any place. The user's equipment information and operation data are available through the Internet. Transfer to the monitoring center to achieve big data management. Provide an intuitive, fast, and comprehensive management platform for equipment managers and manufacturers to improve management efficiency. By long-term operation of the system, obtain long-term operation data of the equipment, and effectively upgrade the equipment based on big data.

The GDIS-E2000 system is a centralized monitoring system for large internal combustion engines (diesel engines, natural gas engines, gas engines, etc.), providing monitoring systems for engines and generator sets for CPC Jichai. The system can monitor the operating conditions of domestic and foreign units, collect equipment identity information, real-time operating data, and historical operating data of all running engines, and provide necessary services to customers quickly and effectively.

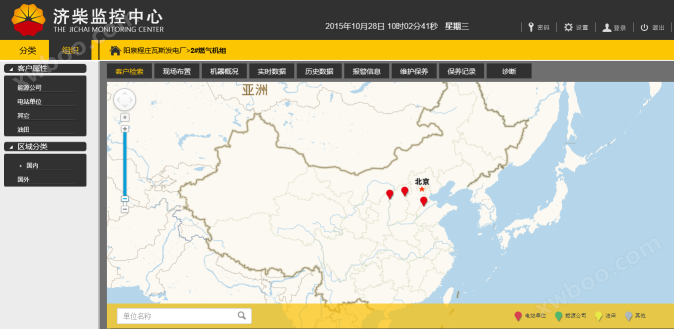

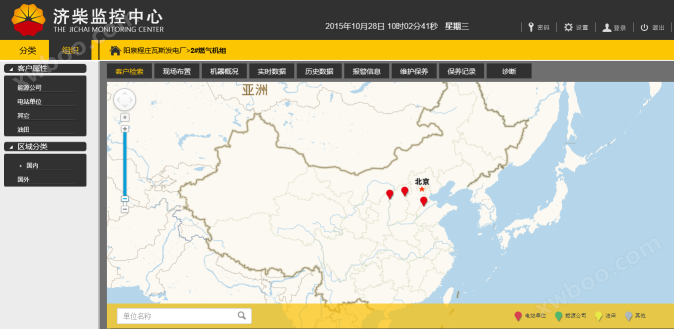

Equipment area positioning

Utilizing the Global Positioning System to locate device location information in real-time, particularly suitable for devices that frequently move. The system provides location information of the device, including altitude, latitude and longitude, and accurate time information. Equipment suppliers and service providers provide fast repair and service services to users quickly, directly, and efficiently based on device location information, improving efficiency.

Real time operating conditions of equipment

By using real-time operating conditions of the equipment, the identity information of the equipment can be obtained, including factory information, equipment operation history, and current operation overview, to quickly grasp the overview of the equipment. By obtaining device information, the system can quickly query the historical events of the device, and quickly search for device production and historical information. By obtaining real-time operational data of the equipment, it greatly facilitates the management and maintenance personnel to provide data basis for the safe and reliable operation of the equipment, and can efficiently and quickly grasp the overview of equipment operation.

Equipment data analysis

Equipment data analysis is a microcosm of big data analysis for the GDIS-E2000 system. By utilizing this feature, it is possible to analyze the historical operational data of standalone devices, perform trend analysis on mixed data types, and transition from planned maintenance to data maintenance. Through table data analysis, detailed analysis of various contents of the equipment can be achieved, and targeted inspection and analysis of equipment operation can be carried out. Through curve analysis, the operating trend of equipment over a period of time can be achieved. By comparing mixed types of curves, deeper performance and fault diagnosis of equipment can be achieved, effectively avoiding hidden faults.

Equipment maintenance reminder

The GDIS-E2000 system provides a scheduled maintenance reminder function, which is set according to the maintenance cycle designed by the equipment manufacturer and actual experience. The equipment maintenance reminder is achieved through a color progress bar (using a gradient color progress bar). Ensure timely inspection and maintenance by users, guarantee equipment safety and reliability, extend equipment service life, and reduce unnecessary losses.

The system provides various equipment maintenance conditions such as equipment inspection, maintenance, repair, and replacement. It can enter the product number, manufacturing date, product number, etc. of the repaired and replaced parts, and automatically record the maintenance time and personnel information, forming maintenance records for future reference.

--Responsible Editor: Heyuan Intelligent Editor

copyright: http://www.hyzn77.com Please indicate the source when reprinting (from Heyuan Intelligence)